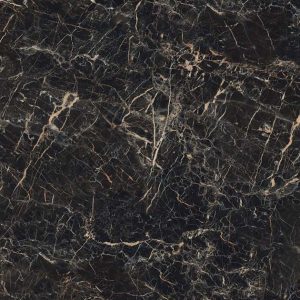

Silica In Engineered Stone - Why Choose Grande Porcelain Slabs

Silicosis is a serious respiratory disease caused by the inhalation of crystalline silica, a mineral found in many types of rocks and soils. This disease is most commonly associated with the mining and construction industries, where workers are exposed to high levels of silica dust during drilling, grinding, cutting, and other activities.

However, silica exposure can also occur in other industries, including the manufacturing of porcelain and engineered stone products. This essay will examine the safety issues surrounding silica sand and its disease silicosis in the manufacturing of these two products, and argue that porcelain is safer to process than engineered stone.

Silica Exposure in the Manufacturing Industry:

Silica sand is used as a raw material in the manufacturing of many products, including porcelain and engineered stone. When silica sand is processed, it can create a dangerous amount of dust that can be inhaled by workers. Silica dust is so small that it can penetrate deep into the lungs and cause damage over time. This can lead to a number of respiratory diseases, including silicosis, lung cancer, and chronic obstructive pulmonary disease (COPD).

Porcelain Manufacturing:

Porcelain is a type of ceramic that is made from a mixture of kaolin, feldspar, and quartz. Unlike engineered stone, porcelain is fired at high temperatures, which makes it less likely to release harmful dust particles into the air during processing. The manufacturing of porcelain involves grinding and milling the raw materials to create a fine powder. This powder is then mixed with water to form a paste, which is then moulded and fired at high temperatures to create the final product.

The manufacturing process of porcelain is relatively safe for workers because the high temperatures involved in firing the product help to eliminate any harmful dust particles that may be present. This makes porcelain a safer product to process than engineered stone.

Engineered Stone Manufacturing:

Engineered stone, also known as quartz or composite stone, is a synthetic material made from crushed quartz, resin, and pigments. Unlike porcelain, which is fired at high temperatures, engineered stone is cured at room temperature with the help of a curing agent. The manufacturing of engineered stone involves cutting and polishing the raw materials to create the final product. This process can create a large amount of dust that can be inhaled by workers.

The manufacturing process of engineered stone is much more hazardous than that of porcelain. The cutting and polishing of the raw materials can release large amounts of silica dust into the air, which can be harmful to workers. The curing agent used in the manufacturing process can also release toxic fumes into the air, which can cause respiratory problems for workers.

Silicosis:

Silicosis is a respiratory disease that occurs when silica dust is inhaled into the lungs. This disease can take many years to develop, and symptoms may not appear until decades after the initial exposure. Silicosis is a serious condition that can lead to breathing difficulties, lung cancer, and other respiratory problems.

Silicosis is a particular concern for workers in the manufacturing industry, where exposure to silica dust is common. This disease is most commonly associated with the mining and construction industries, but it can also occur in other industries, including the manufacturing of porcelain and engineered stone products.

Preventing Silicosis:

The best way to prevent silicosis is to reduce exposure to silica dust. This can be done by implementing safety measures in the workplace, such as using protective equipment and following safe work practices. Employers can also use engineering controls, such as ventilation systems, to reduce the amount of dust in the air.

In conclusion, porcelain is safer to process than engineered stone due to the manufacturing process and the associated safety issues surrounding silica sand and its disease silicosis. The high temperatures involved in firing porcelain eliminate any harmful dust particles that may be present, making it a safer product. Browse our range of Grande Porcelain Slabs.